Thinking of Concrete Mixture Fatigue Life-Span? We recommend Servo-Pneumatic Four Point Bend Apparatus.

Four-Point Bending Fatigue Test

The Four-Point Bending Fatigue Test is currently the most well-known, standardized popular fatigue test. USA, Europe and China have all listed the four-point bending fatigue test to be the standard measurement for concrete mixture fatigue life-span.

Standards

JTG E20 T0739

AASHTO T321

EN 12697-24D

EN 12697-26D

JTG E20 T0739 Testing Standards

|

Frequency

|

10Hz±0.1Hz

|

|

Temperature

|

15°C±0.5°C

|

|

Loading Type

|

Strain Control Continuous Partial Sine

|

|

Initial Steepness Module

|

The 50th Load

|

|

End Test Standard

|

50% Initial Steepness Module

|

|

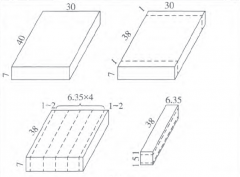

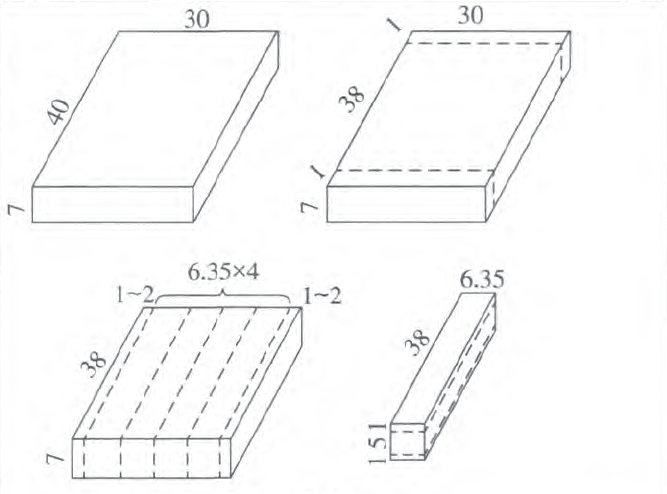

Beam Size

|

Length 380mm±5mm

Height 50mm±5mm

Width 63.5mm±5mm

|

Testing Equipment

Controls & IPC Stand-Alone Servo-Pneumatic Four-Point Bend Apparatus

Controls & IPC Stand-Alone Servo-Pneumatic Four-Point Bend Apparatus

Possible Combinations

Combination 1: Stand-Alone Servo-Pneumatic Four-Point Bend Apparatus + UTM Temperature Controlled Cabinet

Pro: This viable combination has excellent functionality

Con: Long Fatigue Testing Period. In a 10Hz frequency, loads 36,000 periods/hr. However, in a fatigue test will require millions of cycle periods. During this period, the machines cannot be used for other purposes.

Combination 2: Stand-Alone Servo-Pneumatic Four-Point Bend Apparatus + Stand-Alone Temperature Controlled Cabinet

This combination system uses aerodynamics to increase compressive loading. This allows the stand-alone temperature controlled cabinet to perform the experiment, while non-affecting the UTM system to be put into other use.

Combination 3: Four-Point Bending Apparatus + UTM System

As aerodynamic system increases only around 5kN of compressive loading. In cases where materials contain high stiffness would result in unable to cause deformation.

Cooper Stand-Alone Servo-Pneumatic Four-Point Bend Apparatus

Features

Features

-

Frequency range 0.1 to 30Hz¹

-

Low cost pneumatic stand alone four point bending machine

-

Utilizes a low-friction actuator and high performance ceramic spool servo-valve

-

On-specimen measurement system removes errors due to frame flexure

-

Accepts AASHTO beam sizes

-

Sinusoidal controlled strain or controlled stress fatigue test modes

-

Constant torque motorized specimen clamping to eliminate errors due to localised beam indentation

-

Self-contained loading system

-

User friendly software for determination of fatigue resistance and stiffness modulus

-

Supplied with certification of a UKAS accredited calibration

Testing Procedures

Specimen Conditioning: Specimen is put into the environmental chamber for curing, at a temperature of ±0.5°C for more than 4 hours.

Once the specimen has been conditioned, transfer to four-point bending machine.

Choose for suitable testing settings.

Choose for suitable testing settings.

Allow for 50 cycles at target experiment below water level.

Run experiment, when experiment meets the fatigue test requirements, it is programmed to automatically stop.

Testing Report

The same asphalt material mixture should be tested at least 3 times under the same circumstances and conditions. The experiment results should be examined and the non-biased data group should be excluded from calculations. The non-biased data group is determined as from measurement data and average data, when the value differs of k times. The non-biased data group should be discarded under such circumstance.