Industry standards of Ministry of Housing and Urban-Rural Development

Announcement of "Technical code for testing of building foundation piles"

The “Technical code for testing of building foundation piles” (JGJ/T69-2019) is now approved as the industry standard, which will be implemented on 1 June 2019. The original "PY type pre-drilling side pressure test procedure" (JGJ69-90) was abolished at the same time.

This standard is published on the website of the Ministry of Housing and Urban-Rural Development (www.mohurd.gov.cn) and published by the China Building Industry Press, Institute of Standardization of the Ministry of Housing and Urban-Rural Development.

Ministry of Housing and Urban-Rural Development of the People's Republic of China

27 March 2019

This announcement indicates the updated and revised version of the PY pre-drilled side pressure test procedure, which has been used for nearly 30 years in China.

In the past 30 years, many new equipment have been introduced due to the fast development of China's in-situ testing technology. In order to adapt the new situations and equipment, it is necessary to make some adjustments to relevant specifications. Compared with the old and new specifications, the biggest change is the addition of a self-drilling pressure gauge. The original specification is applicable to the pre-drilling side pressure test and the new specification incorporates the self-drilling side pressure test.

1. What is a pressure test?

Pressure meter test (Pressuremeter Test):

In the borehole, an in-situ test method deterges the relationship between soil pressure and deformation by applying radial pressure to the test section wall corresponding deformation of the soil.

2. What types of pressure test are there?

At present, method of placing the pressure probe in the soil can be divided into three types:

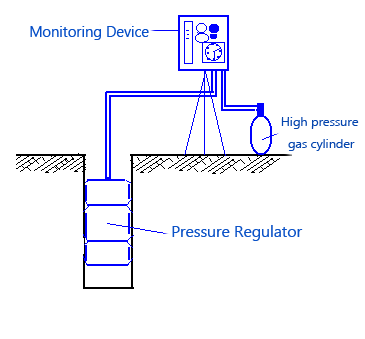

● Pre-boring Pressure Meter Test: The pre-forming hole is used to put the pressure reducer into the hole, and the ground soil will deform when applying radial pressure to the test hole wall to measure the soil. An in-situ test method for the relationship

between pressure and deformation;

● Self-boring Pressure Meter Test: Install the pressure regulator on the drill pipe. The bottom end of the pressure regulator is equipped with a rotary cutter. When drilling, it will enter the predetermined depth of the soil layer and test after stopping the drill.

An in-situ test method for measuring the relationship between pressure and deformation of various soil layers by applying radial pressure to the wall which causes the corresponding denaturation of the soil foundation;

● Press-in pressure test: no pre-drilling is required. The static pressure is used to press the probe into the soil layer then the probe is pressurized.

3. What is the scope of application of the pressure test?

Pre-drilling side pressure test:

Applicable to cohesive soil, silt, sand, residual soil and gravel soil. It can be used for extremely soft rock and soft rock when experienced.

Self-drilling side pressure test:

Applicable to soft soil, soft plastic, plastic clay soil and silt and sand.

4. What is the use of the data from the pressure test?

The data measured by the pressure test can be used to:

● Cohesive soil consistency state and sand compaction division

● Foundation bearing capacity calculation

● Pile foundation bearing capacity calculation

● Foundation deformation calculation

5. What are the related terms of the pressure test?

● Initial pressure

The pressure measuring chamber is placed at the test position. It is inflated to contact the wall of the hole and disturbs the soil to return to the earth pressure value corresponding to the original state.

● Critical pressure

The pressure value corresponding to the end point of the straight line segment of the test curve.

● Extreme pressure

After the plastic pressure on the pressure test curve, the pressure value corresponding to the asymptote of the vertical pressure axis of the curve segment

● Modulus of pressuremeter

The deformation parameters of the obtained foundation soil are calculated according to the pressure test and the slope of the straight line segment of volume or the unique curve.

● Poisson’s ratio

When the rock mass is axially stressed in the elastic range, the ratio of transverse strain to axial strain

6. What are the instruments for the pressure test?

1. Mena pressure gauge

The most classic pre-drilling side pressure

The side pressure test originated in Germany in 1933 and was invented by Kogler. It was originally an instrument for lateral load testing in boreholes, the earliest prototype of a single-chamber pressure gauge. In 1957, the French engineer Luis Mena developed a three-chamber pressure gauge.

Features of the Mena Pressure Gauge

● consists of control unit, tubing and three-chamber probe

● Complies with: ISO 22476-4 and ASTM D-4719-00 standards

● Volume range: 800cm3

● Pressure regulating valve range: 0 ~ 2.5MPa; 0-6MPa; (When performing soft rock test, optional 10MPa pressure gauge)

● Pipeline: coaxial or dual pipeline, flexible, low deformation under high pressure, connecting probe and control unit

● Probe: three-cavity probe, central cavity (applying water pressure), two protective chambers (applying air pressure), balance the pressure of the three chambers through the differential pressure regulating valve to ensure the measuring chamber is a true cylinder deformation.

● Data can be read manually or automatically collect by GeoBox data acquisition instrument

● Test data can be analyzed and processed using GeoVision software

2. GeoPAC

It is the first Mena pressure gauge in the market that is fully automated and performs all of the different test steps autonomously in accordance with the operator setup steps. For the operator, GeoPAC® makes the entire test process easier to control. It enhances the reliability of the test results and reduces the test preparation time. The original system provides two physically separate piping circulators necessary for the Mena pressure test: gas and water (original design, never seen on the market). Benefit from the technological level of the water circulation system, the control accuracy of the water volume of the system has reached an unparalleled level.

GeoPAC Specifications

● Size: 1000*380*340mm

● Weight: 45kg (when vacant)

● Maximum air pressure: 70 bar

● Power requirement: 9~18VDC

● Volume measurement process: about 1200cm3

3. HyperPAC

The HyperPAC® high pressure automatic control pressure gauge is powered by GeoBOX®. HyperPAC® was developed for high pressure testing in rock and very hard formations. It is the first pressure gauge in the market that is fully automated and performs all of the different test steps autonomously in accordance with the operator setup steps. For the operator, HyperPAC® makes the entire test process easier to control, enhances the reliability of the test results and reduces test preparation time.

HyperPAC® Technical Specifications

● Size: 1000*380*340mm

● Weight: 40kg

● Maximum hydraulic pressure: 250 or 500 bar

● Power requirement: 9~18VDC

4. Cambridge Radial Pressure Gauge (RPM)

Press-in pressure gauge

The press-in pressure gauge presses the probe into the soil layer by means of static pressure. A special case of this method is the cone pressure gauge (CPM), which is connected to the pressure gauge by a cone with a cross-sectional area of 15cm2 and has the same diameter as the pressure gauge. Material disturbances have an effect on both. With this loading path, the only parameter available is the ultimate pressure of the soil. This method quickly tests the soil that any cone probe can press. The most attractive aspect of this method is the ability to perform both profile analysis and direct measurement of soil strength and stiffness.

Radial Pressure Gauge Specifications

● Diameter, length: 46mm, 900mm

● Extended length: 255mm

● Aspect ratio: 5.5:1

● Rated pressure: 10MPa, 100bars

● Maximum pressure: 12MPa, 120bars

● Displacement measurement: The cantilever spring of the 3 bridge strain measurement is on the same horizontal plane. The output is a function of the film radius.

● Strain range: Each displacement device has a range of variation, that is, 45% of the diameter of the outward expansion along the 49mm pupil, and the volume expansion is about 80%.

● Pressure measurement system: original film pressure measurement under the hole

● Expansion method: compressed gas and manual regulator

● Under-hole electronics: Plug-ins include amplifiers, voltage regulation and similar digital conversion components

● Resolution: pressure 0.1kPa / 1μm (strain equivalent to 2.1x 10-5), shear modulus is equivalent to measured 4GPa

5. Cambridge self-boring pressuremeter(SBPM)

The probe of the self-drilling pressure gauge is a micro-boring machine. The drill provides power to drive the drill on the probe to rotate. After reaching the test depth, the probe is pressure-expanded to test the surrounding soil. Self-drilling pressure gauges use sensors to measure the pressure applied to the soil and the deformation of the soil with a very high precision. Moreover, the probe also has a pore water pressure sensor, which can measure the pore water pressure and obtain more parameters.

Self-drilling pressure gauge specifications

● Installation method: self-drilling

● Initial diameter: 83-89mm, depending on the configuration

● Length of abandoned soil: drill at least 1 meter before testing

● Displacement measurement system: three strain sensors are evenly distributed in the test hole for one week

● Displacement measurement resolution: less than 1μm

● Pressure measurement resolution: 0.1kPa

● Maximum expansion: 15% larger than the instrument is at rest

● Maximum working pressure: 10MPa

6. AM manual pressure gauge

The TEXAM pressure gauge is a reliable and economical test facility for evaluating most geotechnical problems. It has modular design and manual pressurization. It is used to perform load tests of different depths on site according to conventional requirements. This test method was developed by Louis Menard has been well documented. It is used to interpret the test results and to analyze the following parameters:

● Shallow foundation and bearing capacity of deep foundation

● Various basic settlements

● Deformation of various sheet piles and piles subjected to lateral loads

● The friction of the anchor

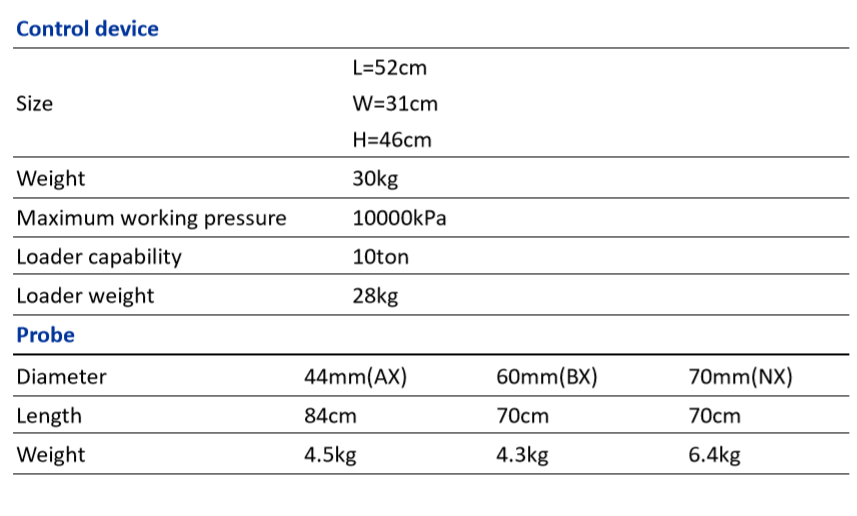

TEXAM technical specifications

For more information, please contact Earth Products China Limited.

Service hotline: 400-700-9998

Email: marketing@epc.com.hk

Official website: www.alannabailey.com