Reinforced concrete structures are the main structural form of modern architecture. In the structure of reinforced concrete, the raw materials, diameter, quantity, anchor length, lap length, location, strength and the internal uniformity of the concrete affects the safety and durability of the structure. At the time of acceptance, the diameter of steel, the length of the anchor, the lap length and the raw material of the concrete can be controlled easily. The position of the steel reinforcing bar will be displaced by the vibration caused by artificial stepping and pouring of concrete. The physical strength and internal uniformity of the concrete will be affected by factors such as concrete vibration, formwork installation, maintenance and loading. To maintain the quality of the reinforced concrete structure, an inspection of the main structure should be carried out after the completion of the construction. After passing the inspection test, a complete quality control data will be collected and the engineer director will organize the project division to accept the acceptance. After the acceptance is passed, the decoration and renovation project can be entered.

1. Which part needs to do physical entity test?

Important parts related to the safety of concrete structures. The shear wall, columns and rafts are examples of unimportant parts of structural safety.

2. What are the participating units and personnel for structural entity test?

Under the witness of the supervision engineer, the project technical person responsible to organize the implementation of the structural entity test and entrust a laboratory with corresponding qualifications to carry out the structural entity test.

3. What are the main contents of structural entity test?

On-site inspection of concrete, mortar, masonry strength and thickness detection of steel protective layer. Structural performance testing of concrete prefabricated components and mechanical properties testing of post-embedded parts.

4. What are the test methods for concrete strength?

Non-destructive (e.g. rebound method, ultrasonic method) or partial damage method (e.g. core sampling); based on the strength of the same condition test.

5. What are the requirements for the thickness of the protective layer of the steel reinforcing bar?

1. The structural part is jointly selected by the supervision, construction unit and other units (the routine practice at the construction site is selected by the laboratory).

2. Number of components: beam and plate components, 2% of the number of extracted components and not less than 5 pieces.

3. The selected beam-type members are inspected for the thickness of the protective layer of all longitudinally-strength ribs. The selected plate-like members cannot be siphon less than 6 longitudinally-forced bars.

4. The allowable deviation of the thickness of the protective layer of longitudinal force ribs: beam members +10mm, -7mm; plate members +8mm, -5mm.

6. Relevant standard standards for on-site inspection of main engineering structures

-"Technical specification for inspecting of concrete compressive strength by rebound method." JGJ/T23-2011

- "Technical specification for detecting strength of concrete by ultrasonic-rebiund combined method" CECS02-2005

- "Technical specification for inspection of concrete defects by ultrasonic method" CECS21-2000

- Technical specification for test of reinforcing steel bar in concrete" JGJ/T-152-2008

- "Technical specification for testing construction quality by radar method" DGJ32-TJ79-2009

- "Technical specification for inspection of concrete strength by pull-out post-insert method" CECS69:94

- "Technical specification for testing concrete strength with drilled core" CECS 03:2007

-"Technical standard for in-site inspection of concrete structure" GBT 50784-2013

- "Technical specification for testing of concrete defects by impact echo method" JGJ T 411-2017

7. What are the structural entity detection devices?

Concrete strength and uniformity testing equipment, steel reinforcing bar testing and protective layer measuring instruments.

Concrete strength and uniformity testing equipment

• 3D concrete structure imaging (Radar detector)

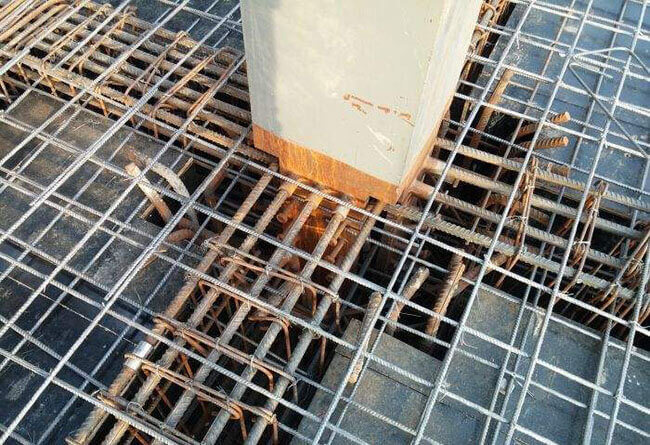

Large-area scanning inspection for the spacing of steel reinforcing bar in structures and components; when the detection accuracy meets the requirements, it can also be used for thickness detection of concrete protective layers of steel reinforcing bar.

-Detection principle

A method for detecting the spacing of steel reinforcing bar and the protective layer of concrete by transmitting and receiving nanosecond electromagnetic waves.

• 3D concrete compressive strength and uniformity imaging (Ultrasonic detector)

Ultrasonic concrete testing can detect voids, pipes and cracks, as well as give information about concrete uniformity, cavities, cracks, defects, and cement board thickness. In addition, measuring pulse speed can also reveal information about the quality of the concrete.

-Detection principle

Ultrasonic probe array is used, 8 channels are arranged in each row, 1 channel transmits signals, the other 7 channels receive echoes, each channel transmits signals in turn, and one complete measurement includes 56 A-Scan for calculating B-Scan And use Synthetic Aperture Focusing (SAFT) for real-time display.

• Concrete compressive strength and uniformity

• Rebound tester

The rebound tester is always used for on-site prediction of concrete compressive strength and the rapid assessment of evaluation.

-Detection principle

A rebounding instrument is used to detect the hardness of the concrete surface, thereby estimating the strength of the concrete.

Rebar inspection and protective layer measurement

• Single steel reinforcing bar detection (Steel detector)

The steel reinforcing bar detector can be used to detect the spacing of the steel bars in the concrete structure, components and thickness of the concrete cover.

-Detection principle

The method of detecting the spacing of steel reinforcing bar, the thickness of concrete protective layer, the nominal diameter of concrete structures and components by electromagnetic induction principle.

• Steel corrosion test

• Half-cell potential method steel corrosion detector

Corrosion of steel reinforcing bar is the main cause of degradation of the reinforcement members. The measured concrete surface can be used to detect points where the likelihood of corrosion increases. It is an important tool for maintenance and evaluation of concrete structures.

-Detection principle

A method for determining the corrosion behavior of steel reinforcing bar by detecting the potential point on the surface layer and comparing it with the copper sulfate reference electrode.

⇒ These instruments are from the long-established manufacturer of NDT products - Proceq, Switzerland.

Proceq is founded in 1954, a world-leading manufacturer of top portable non-destructive testing instruments covering concrete, rock, metal, composites, and paper. Proceq brings technological innovation to the field of non-destructive testing. On the basis of ensuring high quality, Proceq’s products are constantly integrated with the latest electronic technology development concept with novel design, complete functions and convenience, their products are widely used all over the world.

Mid-year promotion

June 15 - August 15

Earth Products China Limited will carry out Proceq product promotion

You can enjoy a special discount when you choose to purchase Proceq products through our company

or

You can get an extra gift from Proceq and other equivalent gifts

To get more details, don’t hesitate to contact us

Earth Products China Limited

Service hotline: 400-700-9998

Official website: www.alannabailey.com