|

Pile Dynamics revolutionizes

Shaft Inspection with the SQUID

Assesses cleanliness and competency of the bottom

ofdrilled shaft or bored piles.

|

|

|

An important part of bored pile / drilled shaft construction is the

cleaning and inspection of the bottom of the hole for cleanliness prior

to the placement of reinforcement and concrete. Once drilling is

complete, any material unsuitable for end bearing support is removed.

Bottom inspection is then performed, often by lowering a camera down the

bore hole, a procedure that gives a rough idea of the thickness of any

debris left at the bottom.

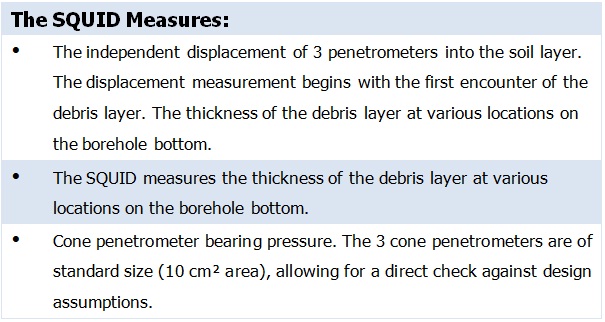

The SQUID (Shaft Quantitative Inspection Device) is an

alternative to the camera-based visual inspection of the excavated shaft

base. SQUID assesses cleanliness by measuring the thickness of the debris

or noncompetent material remaining at the shaft base, and can also

provide a quantitative evaluation of the strength of the bearing layer. A

drill stub column adaptor allows for a quick pinned connection to the

Kelly bar of any drill rig; the rig itself lowers the SQUID body to the

base of the shaft. The SQUID body includes three retractable contact

plates attached to displacement transducers, and one instrumented cone

penetrometer for each contact plate.

|

|

|

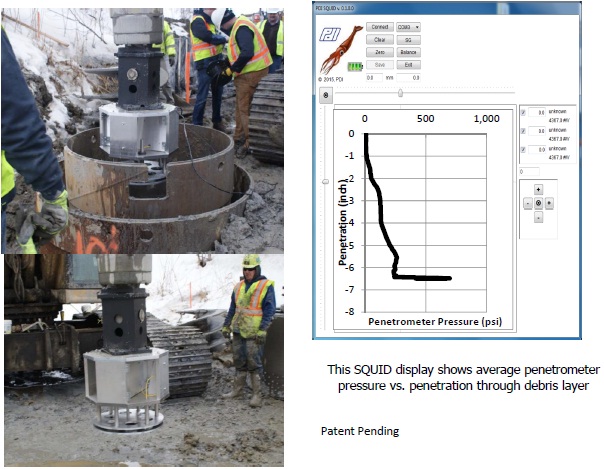

The penetrometer cones move through the debris layer and into the bearing

material under the weight of the Kelly bar and measure pressure, while

the transducers measure displacement. The SQUID body connects by cable to

a wireless transmitter at the edge of the borehole; the transmitter sends

pressure and displacement data to the SQUID Tablet. The wireless data

transmission to the tablet – where data is visualized - allows for the

person holding it to be positioned at a safe distance from the borehole.

The SQUID Tablet displays, among other information, the depth of the

non-competent layer and the maximum penetrometer cone tip pressure.

Click here to download the specification

For more information, please contact:

Ryan Yip at 6017 5294 or email: ryanyip@epc.com.hk

|